About

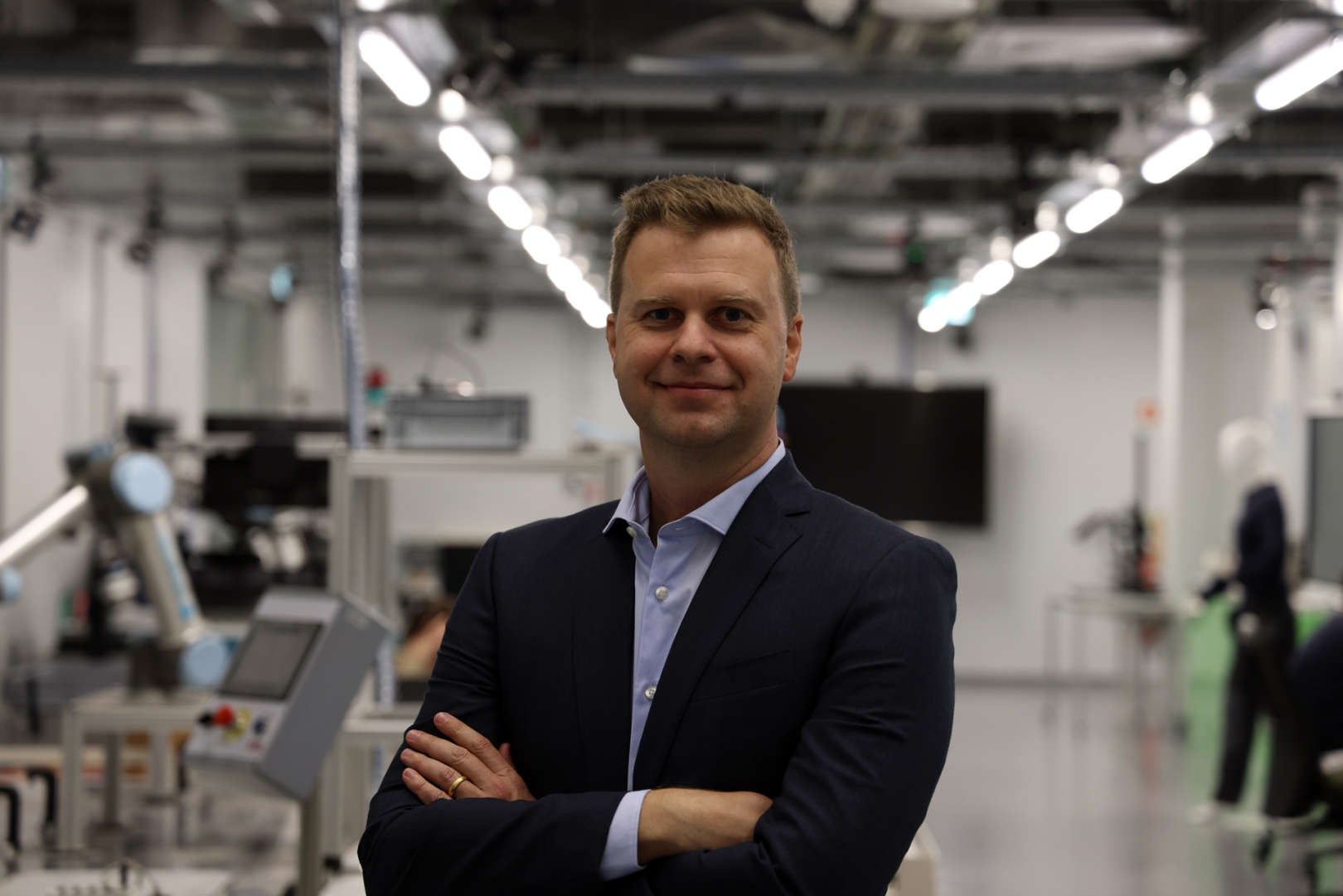

Marcelo R. Petry is a robotics researcher and educator at the Centre for Robotics in Industry and Intelligent Systems at INESC TEC (Portugal). His research lies at the intersection of robotics, computer vision, and extended reality, aiming at the application of robots in manufacturing, logistics, inspection, and human assistance. Marcelo graduated in Control and Automation Engineering from the Pontifical Catholic University of Rio Grande do Sul in 2008 (Brazil) and obtained his PhD in Informatics Engineering from the University of Porto in 2013 (Portugal). Previously, he was an Assistant Professor at the Federal University of Santa Catarina and a researcher at INESC P&D Brazil (2014 to 2019).